The 3D Printing Technology stands out as a transformative force, heralding a new era of manufacturing paradigms. From its humble beginnings as a prototyping tool to its current status as a viable method for producing end-use parts, 3D Printing Technology has evolved by leaps and bounds. In this comprehensive exploration, we delve into the dynamic advancements in 3D Printing Technology, uncovering its profound implications for various industries and its potential to redefine the very nature of manufacturing.

Contents :

The Genesis of 3D Printing Technology:

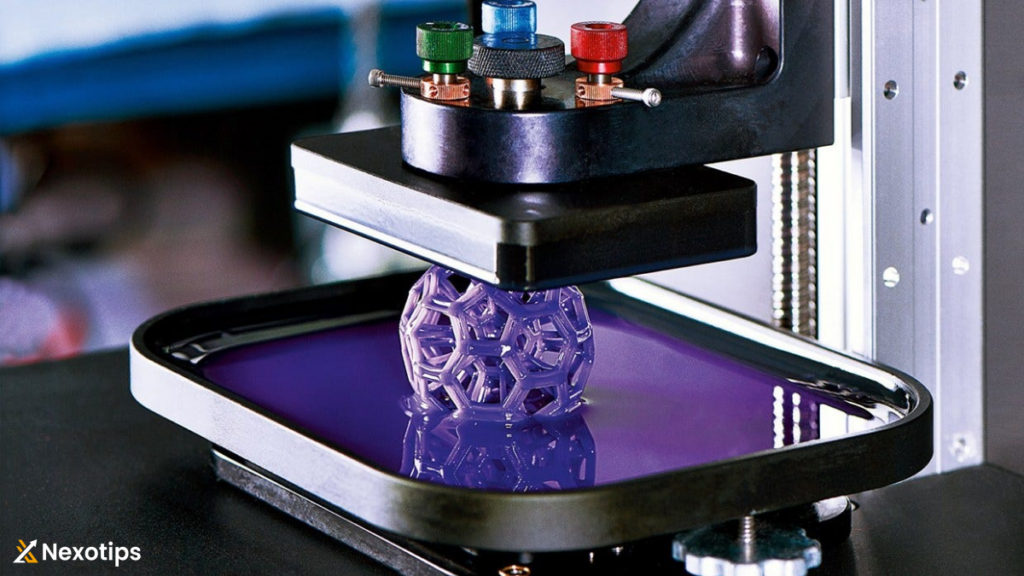

- Origins and historical development: 3D printing, also known as additive manufacturing, originated in the 1980s with the invention of stereolithography (SLA) by Chuck Hull. SLA involves curing liquid photopolymer resin layer by layer using ultraviolet light. This laid the foundation for subsequent 3D printing technologies.

- Early applications and limitations: Initially, 3D Printing Technology was primarily used for rapid prototyping due to its ability to quickly produce complex geometries. However, limitations such as limited material options, slow printing speeds, and relatively low resolution hindered its widespread adoption for end-use parts production.

- Evolution of 3D printing technologies: Over the decades, significant advancements have been made in 3D printing technologies. This includes the development of various printing processes such as selective laser sintering (SLS), fused deposition modeling (FDM), digital light processing (DLP), and electron beam melting (EBM). Each process offers unique advantages and is suited for different applications, contributing to the versatility of 3D Printing Technology.

The Rise of Additive Manufacturing :

- Understanding the principles of additive manufacturing: Additive manufacturing builds objects layer by layer from digital models, as opposed to subtractive manufacturing methods that involve cutting away material from a solid block. This layer-by-layer approach allows for precise control over the geometry of the final part.

- Key advantages over traditional manufacturing methods: Additive manufacturing offers several advantages over traditional manufacturing methods, including reduced material waste, faster prototyping, and the ability to produce complex geometries that are difficult or impossible to achieve with conventional machining processes.

- Expansion of materials and capabilities: Initially limited to plastics, 3D Printing Technology now encompasses a wide range of materials including metals, ceramics, composites, and even biomaterials. This expansion of material options has opened up new possibilities for diverse applications across industries, from aerospace and automotive to healthcare and consumer goods.

Innovations Driving 3D Printing Forward :

- High-speed 3D printing techniques: Traditional 3D printing processes were often slow, limiting their suitability for mass production. However, advancements in high-speed 3D printing techniques such as continuous liquid interface production (CLIP) and high-speed sintering (HSS) have significantly increased printing speeds, making 3D Printing Technology viable for mass production applications.

- Multi-material and multi-color printing: Recent advancements in printing techniques and material formulations have enabled the simultaneous printing of multiple materials and colors within the same object. This capability opens up new opportunities for creating complex, multi-functional parts with varying mechanical properties and aesthetics.

- Advances in precision and accuracy: Improvements in hardware, software algorithms, and calibration techniques have led to enhanced precision and accuracy in 3D-printed parts. This is particularly important for applications where tight tolerances and fine details are required, such as in aerospace, medical, and automotive industries.

- Integration of IoT and automation: 3D Printing Technology is increasingly being integrated with Internet of Things (IoT) technologies and automation systems to enable remote monitoring, predictive maintenance, and autonomous operation of 3D printers. This integration improves efficiency, reliability, and scalability of 3D Printing Technology operations, making it more suitable for industrial-scale production.

- Sustainability and eco-friendly practices: With growing concerns about environmental sustainability, there is a push towards developing sustainable 3D Printing Technology materials and optimizing printing processes to minimize waste and energy consumption. This includes using recycled plastics, bio-based resins, and implementing closed-loop recycling systems to reduce the environmental footprint of 3D printing operations.

Applications Across Industries :

- Aerospace and defense: In the aerospace and defense industries, 3D printing is used for producing lightweight components, complex geometries, and on-demand replacement parts. This enables faster turnaround times, reduced weight, and improved fuel efficiency for aircraft and spacecraft.

- Automotive: Automotive manufacturers utilize 3D printing for rapid prototyping, customized parts production, tooling, and even end-use components such as interior panels, brackets, and engine parts. 3D Printing Technology enables faster iteration cycles, cost-effective customization, and design optimization for improved performance and efficiency.

- Healthcare: In healthcare, 3D Printing Technology is revolutionizing patient care by enabling the production of patient-specific medical implants, prosthetics, surgical guides, and anatomical models. These personalized solutions improve patient outcomes, reduce surgical risks, and enable healthcare professionals to better plan and execute complex procedures.

- Consumer goods: Companies in the consumer goods industry leverage 3D printing to offer personalized products, limited-edition runs, and decentralized manufacturing. This allows for greater customer engagement, faster time-to-market, and customization options that cater to individual preferences and market segments.

- Architecture and construction: Architects and builders use 3D printing for creating intricate scale models, custom building components, and even entire structures. 3D Printing Technology enables faster, more cost-effective construction methods, as well as the realization of complex architectural designs that would be challenging or impossible to achieve using traditional construction techniques.

- Education: Educational institutions incorporate 3D Printing Technology into STEM curricula to provide students with hands-on experience in design, engineering, and manufacturing. By allowing students to design and prototype their own creations, 3D Printing Technology fosters creativity, problem-solving skills, and innovation in the next generation of engineers and designers.

Transformative Impacts on Supply Chains :

- On-demand production and localized manufacturing: 3D printing enables on-demand production of parts and products, reducing the need for large inventories and enabling localized manufacturing closer to the point of consumption. This decentralization of production can lead to shorter supply chains, reduced shipping costs, and improved responsiveness to customer demand.

- Reduction of inventory costs and lead times: By eliminating the need for tooling and reducing setup times, 3D printing reduces inventory costs and lead times, making supply chains more agile and responsive to changing market demands. Companies can produce small batches of parts economically, allowing for just-in-time manufacturing and inventory management.

- Customization and mass customization: The ability to produce customized products on-demand without incurring significant additional costs empowers companies to offer mass customization, catering to individual preferences and market segments. This customization can drive customer loyalty, increase brand value, and differentiate products in competitive markets.

- Resilience and flexibility in response to market fluctuations: 3D printing allows companies to quickly adapt to changing market conditions, whether it’s shifting production to meet sudden demand spikes or rapidly iterating designs in response to customer feedback. This agility and flexibility enhance supply chain resilience, reduce risks associated with inventory obsolescence, and enable companies to stay competitive in dynamic markets.

Challenges and Future Outlook :

- Quality control and standardization: Ensuring consistent quality across 3D-printed parts remains a challenge, particularly for critical applications in industries such as aerospace and medical. Advances in process control, metrology, and material characterization are needed to improve quality assurance and standardization in 3D printing.

- Intellectual property issues: The digital nature of 3D printing raises concerns about intellectual property infringement, as designs can be easily replicated and distributed without proper authorization. Addressing intellectual property issues requires robust security measures, legal frameworks, and industry standards to protect the rights of designers and innovators.

- Scaling up for mass production: While 3D printing excels in low-volume and customized production, scaling up for mass production presents challenges related to cost, speed, and material properties. Advances in printing speed, material science, and automation are necessary to make 3D printing competitive with traditional mass production methods for high-volume applications.

- Regulatory and safety considerations: Regulatory bodies are still grappling with how to classify and regulate 3D-printed products, particularly in safety-critical industries such as healthcare and aerospace. Clear guidelines, standards, and certification processes are needed to ensure the safety, efficacy, and reliability of 3D-printed components and devices.

- Emerging trends and potential breakthroughs: Ongoing research and development efforts are focused on pushing the boundaries of 3D printing technology. This includes advancements in multi-material printing, nanoscale printing, and 4D printing, which promises to add dynamic functionality to printed objects over time. Other emerging trends include the integration of artificial intelligence, machine learning, and robotics to further enhance the capabilities and efficiency of 3D printing systems.

Conclusion:

As 3D printing continues to evolve and mature, its transformative impact on manufacturing across industries becomes increasingly evident. From unlocking new design possibilities and streamlining supply chains to revolutionizing healthcare and consumer experiences, the potential of 3D printing to reshape the way we create, build, and consume is immense. While challenges remain, including quality control, regulatory compliance, and scalability, the relentless pace of innovation and collaboration among industry stakeholders point towards a future where 3D printing plays a central role in driving sustainable, efficient, and customizable manufacturing solutions. As we navigate this exciting frontier, the possibilities are limited only by our imagination and willingness to embrace change.